2.1. 2019

2.1.1. DT194022

Name of project/product : " Research and build software package to calculate centering of ship's shaft system according to bearing load by finite element method ";

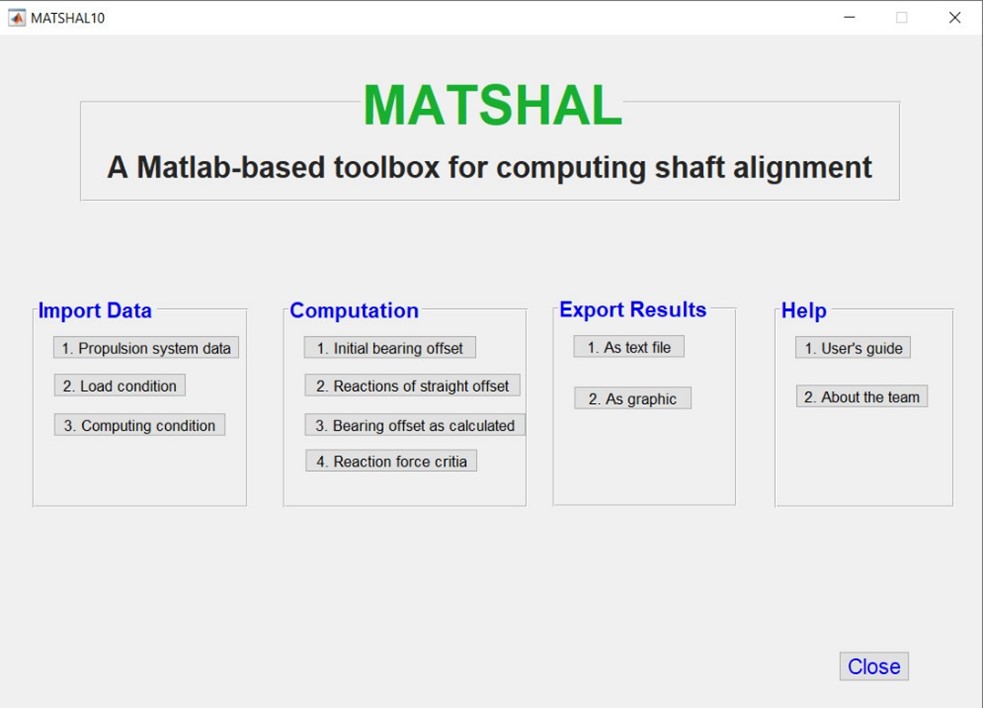

Science and technology product : Computer software for calculating the centering of ship's shaft system according to bearing load criteria , named MATSHAL.

Science and Technology project of the Ministry of Transport in 2019 - Code: DT194022 ;

Information about the project/product team: Project leader: Assoc.Prof.Dr. Pham Xuan Duong ; Members: Dr. Cao Duc Thiep; Dr. Pham Dinh Ba; MSc. Le Dinh Dung; MSc. Nguyen Anh Viet; MSc. Bui Thi Hang; MSc. Do Thi Hien; MSc. Truong Tien Phat; MSc. Pham Van Viet

Description of the project/product :

The goal of the project is to build a software for calculating the centering of the ship's shaft system according to the bearing load criteria (the software is named MATSHAL - Matlab based toolbox for computing Shaft Alignment).

To accomplish that goal, the project team has completed 04 main contents, including: (i) An overview study on centering and calculating centering of ship's shaft system; (ii) Building a finite element model and calculation algorithm for centering the ship's shaft system according to the bearing load; (iii) Programming and testing the newly built software package; (iv) Summary report on the results of the topic.

The obtained results of the project: (i) Type II: MATSHAL software for calculating the centering of the ship's shaft system; (ii) Type III: General report on the results of the topic; (iii) Type IV: 01 Science and Technology article, Training 01 PhD students.

In particular, the MATSHAL software has features divided into 4 main menu groups, specifically as follows (see Figure 1):

(i) Group of data entry tasks for the program (Import Data), including data entry tasks about the propulsion system, main engine, shaft system, propeller,... (Propulsion system data), information input number of different tonnage states of the ship (Load condition) and enter the different calculation states of the ship (Computation condition);

(ii) The group of computational tasks (Computation) includes the tasks of calculating the initial bearing offset (Initial bearing offset), calculating the bearing reaction when the bearings are centered in alignment, the ship on the momentum. (Reactions of straight offset), calculate the bearing correction according to the load criterion (Bearing offset as calculated) and calculate the standard bearing reaction (Reactions force critia);

(iii) The group of export tasks (Export Results) allows to choose two forms of outputting the results: as a text file (As text file) or as graphs (As graphic);

(iv) The group of user support tasks (Help) includes two main contents: the user's guide and the software introduction (About the team).

Picture of project/product :

Image. MATSHAL software working window interface

2.1.2. DT194025

Name of project/product : " Research, design, and manufacture ship's automatic steering system applying adaptive control method ".

Science and technology product : Automatic steering system for ships.

Science and Technology project at the Ministry of Transport in 2019 - Code: DT194025 ;

Information about the project/product team: Project leader: Assoc.Prof.Dr. Tran Anh Dung ; Members: Assoc.Prof.Dr. Dinh Anh Tuan, MSc. Nguyen Thanh Van, MSc. Nguyen Huu Quyen, MSc. Dao Quang Khanh, MSc. Luc Thi Thu Huong, MSc. Le Thanh Lu, Engineer Nguyen Thi Kim Oanh, Engineer Do Thi Chang, MSc. Truong Thi Bich Ngoc.

Description of the project/product :

The ship's autopilot system consists of two separate parts, part 1 is the autopilot station (Figure 1), part 2 is the steering engine (Figure 2). The autopilot control part includes: Steering wheel, PLC device, HMI touch screen, adaptive steering controller integrated on the computer and an interface to set autopilot parameters. All are installed on the electrical cabinet panel of powder-coated steel to withstand the harsh effects of the marine environment. The steering gear is installed under the steering gear tunnel.

The adaptive steering system is used to stably control the ship's course in autopilot mode and improve the control quality thanks to the adaptive algorithm. The steering control part has the function of creating the set course and receiving the actual direction of the train through the onboard electric compass. The system processes the deviation signal between the set and actual directions through a digital adaptive algorithm and outputs a control signal to the steering machine .

Pictures of project/product :

|

|

|

|

Figure 1. Autopilot control part |

|

|

|

|

|

Figure 2. Steering part |

|

2.1.3. DT194032

Name of project/Product : "Research and manufacture ship's shaft jacket on the basis of copper-aluminum alloy with high synthetic mechanical properties, good corrosion resistance and low cost to replace expensive imported goods" .

Science and Technology project of the Ministry of Transport in 2019 - Code: DT194023 ;

Information about the project/product team: Project leader: Assoc.Prof.Dr. Nguyen Duong Nam ; Members: MSc. PhD student Vu Anh Tuan, MSc. Vu Van Tap, Assoc. Prof. Dr. Pham Mai Khanh, MSc. PhD student Le Thi Nhung, MSc. Nguyen Van Bach, Dr. Hoang Anh Tuan, MSc. Nguyen Anh Xuan, MSc. PhD student Bui Thi Ngoc Mai, Engineer Tran Phap Dong.

Description of the project/product :

The topic has proposed two groups of alloys that can be used for making shaft jackets, CuAl9Fe4 and CuAl9Fe4Ni2 alloys with the following mechanical properties:

Hardness Result (HRB):

|

CuAl9Fe4 |

CuAl9Fe4Ni2 |

|

99.5 |

107.5 |

Mass loss result (g)

|

CuAl9Fe4 |

CuAl9Fe4Ni2 |

|

0.1239 |

0.1044 |

Corrosion level results (mm/year)

|

CuAl9Fe4 |

CuAl9Fe4Ni2 |

|

0.0322 |

0.0269 |

The results of the organizational analysis substantiated the research results on mechanical properties and corrosion. The organizational research results show the following:

* Microorganism after casting: The structure of the alloy includes the α phase and the mixture of (α+γ 2 ) mainly. The approximate proportion of the α phase in the studied alloy is 80% and the γ phase is 17%. Dimensions of the α phase after casting of CuAl9Fe4 alloy is 100µm; of CuAl9Fe4Ni2 alloy is 90µm. In addition, in the organization of CuAl9Fe4 alloy Fe 3 Al intermetallic phases appeared with a phase fraction of 2.2%; has a fine small size of about 4 µm and is evenly dispersed in the alloy's organization. The CuAl9Fe4Ni2 alloy has an alternating NiAl intermetallic phase in the phase regions and has a phase fraction of 2.3% with a size of about 3-4 µm.

* Formation of phase after aging: For alloy grade CuAl9Fe4 , change the aging temperature at the temperature range of 350 o C; 450 o C and 550 o C over a period of 02 hours showed that the fraction of α phase increased from 54% in the 350 o C regime to 67% in the 550 o C aging mode. As for the CuAl9Fe4Ni2 alloy grade. aging temperature changes at the temperature range of 350 o C; 450 o C and 550 o C over a period of 02 hours shows that: fraction of α phase increases from 65% at 350 o C mode to 75% at 550 o C aging mode. This shows that with increasing temperature aging the martensite decay process after treating increased.

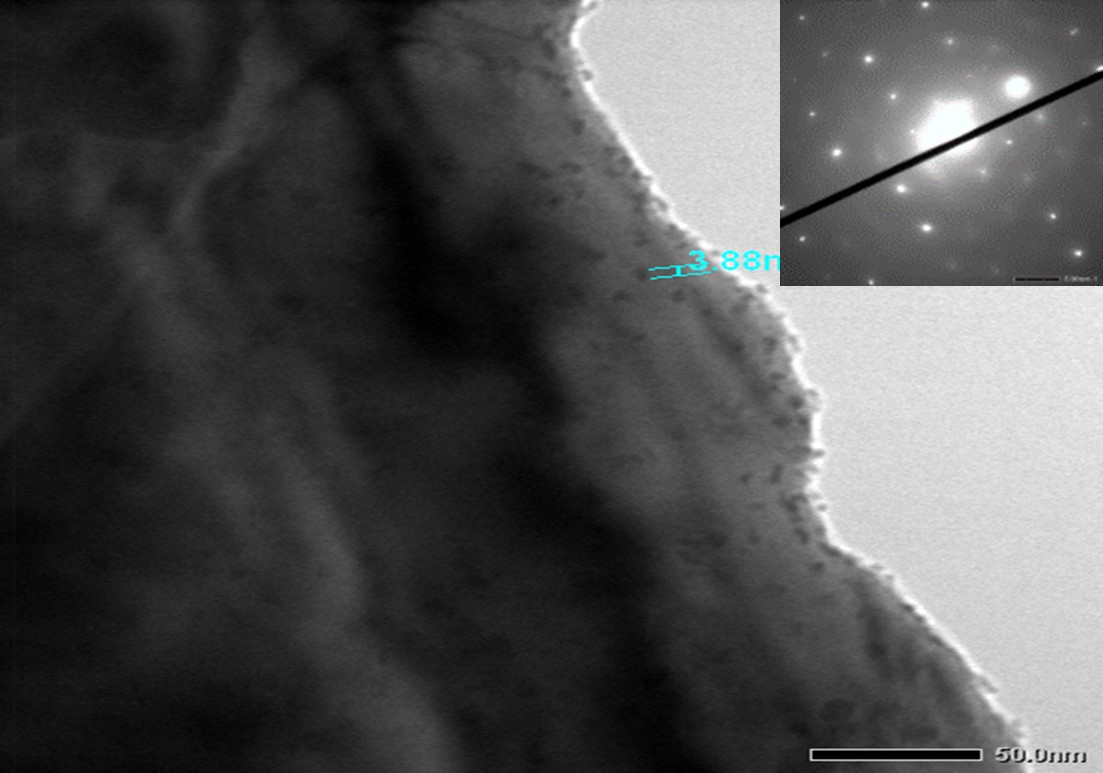

* Identification of martensite and intermetallic phase : TEM analysis of the thesis proved the existence of martensite β' hcp structure with formula Cu 3 Al. At the same time, it also proves that the intermetallic phases formed during the phase transition such as Fe 3 Al.

For the purpose of applying martensite transformation to increase the wear resistance of two grades of research, the topic has determined the relationship of hardness depending on temperature and aging time of two alloy grades:

- CuAl9Fe4 :

HRB 94 = -6.6614+0.3945.T+27.3897.t -0.0005.T 2 -4.5287.t 2 -0.0213.Tt

The mass loss value in the condition of alloy sample research, in the hardness testing modes shows the same variation, the smallest mass defect is m 94 = 0.1239g at the vicinity of the extreme point of the hardness.

- CuAl9Fe4Ni2 :

HRB 942 = -57.7267+0.7386.T+22.45.t -0.0009.T 2 -2.605.t 2 -0.0307.Tt

Picture of project/product:

TEM image analysis at 350 for 02h

2.1.4. DT194038

Name of project/Product : “ Research, design, manufacture and test flow trough equipment ”.

Science and Technology project: The product is the result of a research project at the Ministry of Transport in 2019 - Code: DT194038 ;

Information about the project/product team: Project leader: Assoc.Prof.Dr. Dao Van Tuan ; Members: Bui Quoc Binh, Pham Van Sy, Tran Duc Phu, Nguyen Tien Thanh, Nguyen Thien Thanh, Nguyen Gia Khanh, Pham Ngoc Vuong, Ngo Viet Anh, Tran Van Bon.

Description of the project/product :

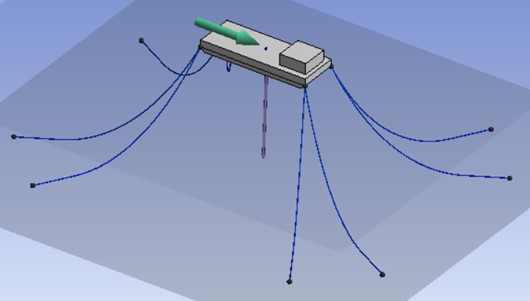

Fabrication of industrial flow troughs. master the design and manufacturing technology of flow troughs, suitable to the level of domestic manufacturing technology, can create a flow suitable for the flow in natural canals and rivers, the size is suitable for the facility. available materials for testing, teaching and scientific research.

Flow trough is designed with dimensions: 5m long, 0.3m wide, 0.5m high, made of shaped steel frame system and tempered glass. The double-ended water tank is 0.5m long, 0.3m wide, 1.2m high, made of a system of shaped steel frames, Ninox corrugated iron and tempered glass.

The pump system consists of a pump and a system of pipes connecting the water tank at both ends of the trough as shown below, demonstrating that the flow velocity in the pump trough is of a large flow type. To measure the pump flow, on the suction pipe, there are 02 pressure sensors attached to calculate the pump flow according to the Venturi tube principle, the pump: pump flow max 132m3/h, using inverter EV06800-43S5D5E20 and Block Control: PLC+ Analog module, HMI display, pressure sensor to control pump flow.

Picture of project/product:

2.2. 2020

2.2.1. DT 203014

Project/Product name : “Research on calculating the mooring line system of marine structures subjected to dynamic loads according to spatial model by Finite Element method ”.

Science and Technology project: The product is the result of a research project at the Ministry of Transport in 2020 - Code: DT203014 ;

Information about the project/product team: Project leader: Assoc.Prof.Dr. Dao Van Tuan ; Members: Bui Quoc Binh, Pham Van Sy, Tran Duc Phu, Nguyen Tien Thanh, Nguyen Thien Thanh, Nguyen Gia Khanh, Nguyen Thi Thu Le, Ngo Viet Anh, Tran Van Bon.

Description of the project/product :

In order for the calculation of the mooring line system to be close to reality, it is necessary to solve the problem in a general way when it is necessary to apply a general-purpose numerical method that is the mathematical method, which allows the calculation of complex linear mechanical systems. and nonlinear, the mooring line system can be calculated in the general case according to the spatial model and subjected to complex dynamic loads, on the mooring line there can be many hanging objects such as buoys and heavy objects.

The actualization of applying the mathematical method can be carried out in two ways: using the commercial software ANSYS- AQWA or using the program based on the algorithm of the mathematical method. The research team solves the problem of calculating the mooring line system to withstand dynamic loads in both directions at the same time.

Develop a process for calculating and oscillating the mooring line system of Marine Works under the load of waves, currents and floating objects according to the spatial model by the Finite Element method.

Instructions on the application of the ANSYS-AQWA module to calculate the mooring line system of Marine structures subjected to dynamic loads.

Picture of project/product:

2.2.2. DT203033

Name of project/Product : " Research, design and manufacture a simulation system suitable for train driver's cabin for training and training ".

Science and technology products : Simulation system for training the train driver's cabin .

Science and Technology project at the Ministry of Transport in 2020 - Code: DT203033 ;

Information about the project/product team: Project leader: Assoc.Prof.Dr. Tran Anh Dung ; Members: Prof. Dr. Dinh Anh Tuan, MSc. Nguyen Thanh Van, MSc. Nguyen Huu Quyen, MSc. Dao Quang Khanh, MSc. Luc Thi Thu Huong, MSc. Dang Dinh Phuc, Engineer Nguyen Thi Kim Oanh, Engineer Do Thi Chang, Engineer Pham Minh Thao.

Description of the project/product :

The ship's cockpit training simulation system is designed and manufactured to resemble the cockpit of a real ship (Figure 1). The maritime training room has a parallel network architecture including 02 network systems, which are Ethernet network and maritime standard network system NMEA0183 to take care of data connection between local devices such as: GPS, GYRO COMPASS, ENCHO SOUNDER, SPEED LOG, AUTOPILOT and ECDIS. The ship's kinematics are based on mathematical equations built in Visual C# and run on a computer simulator. The parameters of the ship are transmitted back and forth with the Workstation PC computer system responsible for creating 2D and 3D images of day and night effects, weather, marine environment such as waves, wind, ocean currents. The image of the ship's maneuvering seen from the Bridge House cockpit is shown in 03 43-inch LCD screens. Environmental situations, strange ships, technical situations can be generated by a teacher computer for training students. Coordinate data, bow direction, speed, seabed depth are transferred to GPS devices, compasses, tachometers, depth gauges and electronic charts for operators to exploit and monitor. The autopilot system will provide the steering angle to the ship model computer and from the deviation of the course from the set direction will give the steering action when operating the autopilot. NFU, HAND and AUTO/PID driving modes are all integrated, steering engine alarm situations such as oil level, overload, phase failure, power failure can be generated from the teacher's computer. In addition, the command bell system, remote control of the main engine diesel are integrated on the marine control panel to communicate with the engine room.

Picture of project/product:

Figure 1. Marine training room

2.2.3. DT203054

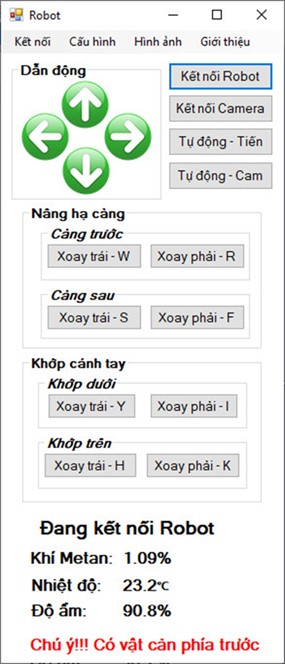

Project/Product Name : “Research, design, manufacture and test a robot for inspecting ballast water tanks of ships ”.

Science and technology product: Robots for inspection of ship ballast tanks .

Science and Technology project: The product is the result of a research project at the Ministry of Transport in 2020 - Code: DT203054 ;

Information about the project/product team: Project manager: Ass.Pro. Nguyen Kim Phuong ; Members: PhD. Nguyen Trong Duc, Ass.Pro. Tran Ngoc Tu, PhD. Phan Van Hung, PhD. Pham Van Tan, MSc. Tu Manh Chien, MSc. Pham Van Luan.

Description of the project/product :

Inspection of ballast water tanks on board ships is an important task, periodically carried out in accordance with the regulations and requirements of the International Maritime Organization (IMO), Flag State and the requirements of planned maintenance system on ships (PMS) which is built specifically for ships . The inspection of ballast water always has potential risks and hazards that can cause accidents, incidents lead to deaths for the inspectors. Therefore, using a robot to replace human in inspecting the ship ballast water tanks will avoid accidents and risks to the inspectors and save time and manpower when conducting the inspection of ballast water tanks on board ships.

Pictures of project/product:

2.2.4. DT203056

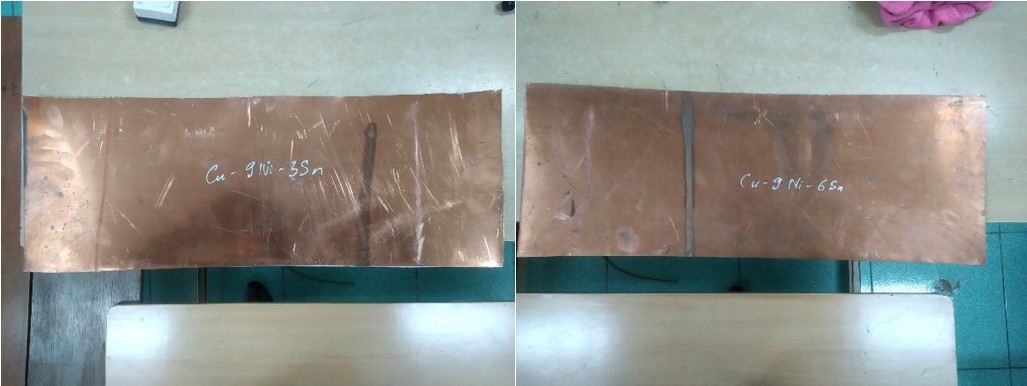

Project name/Product : “Research, manufacture, and test copper alloys based on Ni and Sn alloys with low cost, durability, elasticity and high conductivity for electrical equipment on ships in order to import substitution ”.

Science and technology products : Copper alloy based on Ni and Sn alloying.

Science and Technology project of the Ministry of Transport in 2020 - Code: DT203056 ;

Information about the project/product team: Project leader: Assoc.Prof.Dr. Nguyen Duong Nam ; Members: MSc. Trinh Thi Phuong Lan, MSc. Nguyen Van Bach, MSc. Vu Viet Quyen, MSc. Bui Thi Ngoc Mai, KS. Le Dinh Nghiem, MSc. Pham Hoang Nghia, MSc. Le Thi Nhung, MSc. Vu Thi Thu Trang.

Description of the project/product :

Applying spinodal decomposition theory based on the spinodal transformation region of the alloy system, the project is to research and fabricate a successful heat treatment for Cu-Ni-Sn alloy in three different composition regions: Cu-9Ni-3Sn and Cu-9Ni-6Sn.

- Cu-9Ni-3Sn alloy system is treated with the following process:

Homogenize and quench at 850 0 C;

Hot deformation to specified size then cold deformation 40%;

Aging at 350 0 C for 2 h.

After treatment the strength value increases to over 1000MPa (strength value is equivalent to Cu-Be), hardness value 20HRC, elongation 8%, electrical conductivity about 14%ICAs perfectly in accordance with the contact details.

- For Cu-9Ni-6Sn alloy system treated with the following process:

Homogenize and quench at 850 0 C;

Hot deformation to specified size then cold deformation 40%;

Aging at 3500C for 2h.

After processing the strength value increases above 1200MPa (strength value is equivalent to Cu-Be), hardness value above 26HRC, conductivity 8%ICAs of this alloy can also be applied to the components. Details make electrical contacts, shaft bearings have high elasticity.

During the research, it was discovered that with the Cu, Ni, and Sn functions as above, after heat treatment, the hardness value increases but at a certain temperature the hardness value decreases. By scientific research methods (DSC analysis, Xray analysis, FESEM imaging, mapping) it has been discovered that the alloy has spinodal decomposition that helps the strong strengthening process: the process of strengthening by small particles with function amount of Cu-9Ni-3Sn; Cu-9Ni-6Sn.

When conducting deformation and aging of Cu-9Ni-3Sn alloy; Cu-9Ni-6Sn, strength and hardness values increase strongly because in addition to spinodal decomposition, there is also a combination with small grain deformation process. In this case there is a combination of strain-strengthening and spinodal-strengthening effects.

Pictures of project/product:

2.3. 2021

2. 3.1. DT214013

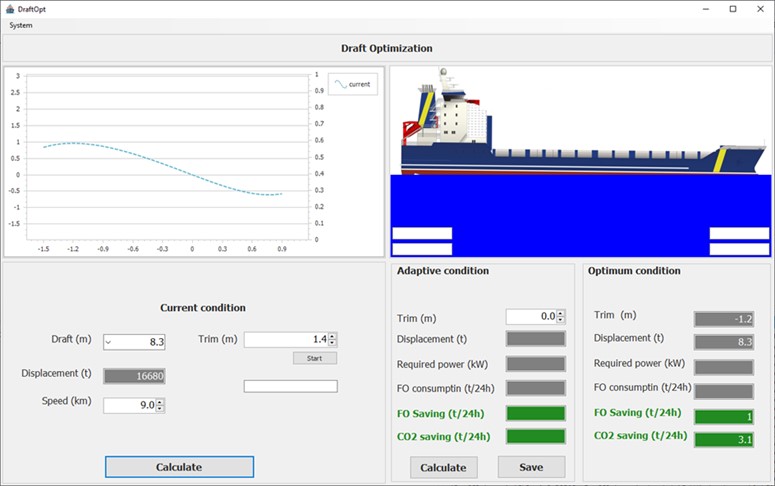

Project/Product name : “Research and develop an automated program to calculate the optimal trim in operation for a group of Vietnamese ships with a deadweight tonnage of 12,500 tons in order to save fuel consumption ”.

Science and Technology Product: Automated system to determine the optimal trim for ships of 12,500 tons .

Science and Technology project: The product is the result of a research project at the Ministry of Transport in 2021 - Code: DT214013 ;

Information about the project/product team: Project manager: Ass.Pro. Nguyen Kim Phuong ; Members: Ass.Pro. Tran Ngoc Tu, PhD. Nguyen Trung Duc, MSc. Tran Quoc Chuan, MSc. Tu Manh Chien, MSc. Pham Van Luan, MSc. Tran Tien Luong.

Description of the project/product :

Trim optimization is one of the new solutions recommended by the International Maritime Organization (IMO) in the Energy Efficiency Operational Indicator (EEOI). To implement this solution in the actual ship operation, the relationship between the trim and ship resistance during the voyage needs to be. This research presents the results of a simulation study on the influence of the trim on the resistance of 12500DWT cargo ship by using CFD method. The result of the relationship between ship resistance and trim at a given speed and loading state definitely helps the Master make an effective energy-saving ship operation plan.

Pictures of project/product:

2.4. 2022

2.4.1. DT223028

Project/Product Name : “Virtual reality simulation in training communication skills for hand-held VHF machines for Vietnamese seafarers ”.

Science and Technology project of the Ministry of Transport in 2022 - Code: DT223028 ;

Information about the project/product team: Project leader: Assoc.Prof.Dr. Nguyen Manh Cuong ; Members: Assoc.Prof.Dr. Nguyen Kim Phuong; Dr. Do Van Cuong; Dr. Mai Xuan Huong; Dr. Phan Van Hung; Dr. Nguyen Trung Duc, MSc. Pham Van Luan.

Description of the project/product :

The impressive development of technology has helped the science, engineering and education sectors achieve great achievements. The application of 4.0 technology in maritime training and education is an inevitable trend. VR virtual reality simulation technology is a field that has been developed very early in the world, but it is still quite new for domestic research. The product focuses on building an immersive VR simulation program for VHF Sailor devices using Unity software, through which users can experience manipulating the device's functions with virtual reality glasses like with real devices, which is aimed to improve communication training for students and crew members of the deck industry at Vietnam Maritime University.

Pictures of project/product: